Pre-finishing Provides Superior Results

Improve the Quality of Your Product

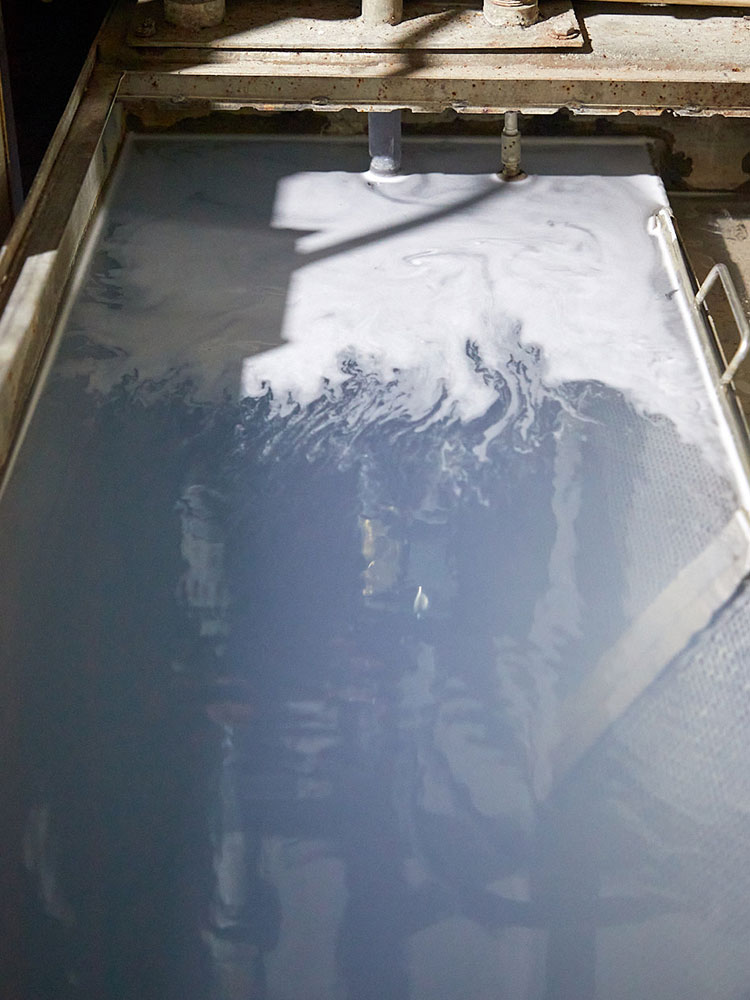

Thorough preparation of a metal surface is the first step to getting a perfect, high quality powder coating. Pre-finishing involves cleaning dirt, oil, grease or other contaminants off the metal to create smooth, blemish-free surface for the paint to adhere to. Jensen Powder Finishers offers a full range of pre-finishing services, including a multi-stage nanotechnology wash system, and we can help determine which processes are right for your project.

Pre-finishing Services:

Capabilities

Get in touch

Call Us Today:

262-886-1212

Pre-finishing Benefits:

- Surface Preparation: Ensures that the surface is free from contaminants, oxidation and any imperfections that could compromise the adhesion of the powder coating.

- Adhesion: Powder coating adheres more effectively to a clean and properly prepared surface, resulting in a more durable and long-lasting finish.

- Smoothness: Smooths out any rough spots or imperfections on the surface for a smoother and more uniform appearance once the powder coating is applied.

- Durability & Corrosion Resistance: Creates a protective barrier between the substrate and environmental factors such as moisture, chemicals and UV radiation. This helps enhance the durability, improve corrosion resistance and increase the longevity of the powder coating finish.

- Appearance: Improves the overall appearance of the product by ensuring that the surface is free from blemishes, scratches or other defects that may become more visible once the powder coating is applied.

- Cost-effectiveness: Ultimately leads to a better-quality finish, resulting in cost savings over the long term by minimizing the need for touch-ups or repairs.

Jensen Powder Finishers is dedicated to serving our clients with the highest level of craftsmanship and customer service. For all your powder coating requirements, trust us to deliver results that exceed expectations. Contact us today to discuss how we can support your next project with our exceptional powder coating capabilities.